The installation of automated logistics systems requires a more demanding floor than you might think. It’s important to ensure that compliance is in expert hands.

Thanks to advances in technology, there are now countless types of automated systems to choose from to meet your individual needs. It is important to note, however, that these systems place a wide variety of demands on industrial concrete floors, both in terms of load and, above all, in terms of flatness.

Automatized & Robotized Warehouses

Warehouse Automation

Rely on the experts to guarantee the right quality so that your warehouse can accommodate automated systems without any problems!

Whatever type of automated logistics system you wish to install, we will ensure that your floor will serve it without any problems during use.

AMR - Autonomous Manoeuvrable Robots

AMR technology uses small, self-propelled robots that move shelves of a given size, typically loaded with smaller products.

Because the robots move freely along designated paths, free-flowing traffic requires a high level of floor accuracy for smooth operation.

ACR - Autonomous Case-handling Robot

ACR systems use robots that can move several storage boxes of a given size at the same time in an autonomous and systematic way.

As the robots move freely along the designated paths, the free flow of traffic requires a high level of floor accuracy for smooth operation.

AGV - Automatic Guided Vehicles

AGV robots are material handling devices that can independently perform everyday material handling tasks.

As the robots are free to move along designated routes, the free movement of the robots requires a high level of flooring accuracy for smooth operation.

RGV - Rail Guided Vehicles

RGV technology equipment uses tracked robots to move pallets and special products.

As the robots run on specific rails, the flatness of the areas where the rails are installed is the most important factor.

AS/RS - Automated Storage and Retrieval System

AS/RS logistics systems typically use robots moving along aisles at high heights to load and unload products onto pallets stored in the warehouse.

AS/RS equipment moves on a fixed track, so the flatness of the areas involved is critical for smooth deployment.

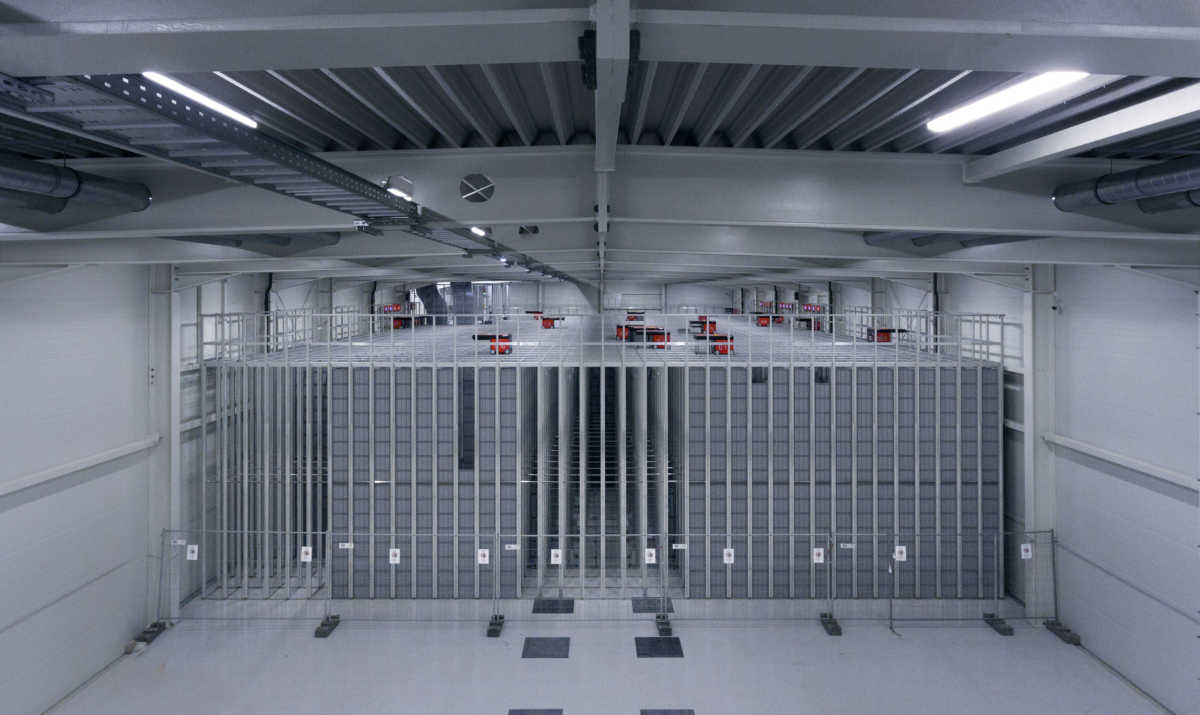

AutoStore System

AutoStore systems are among the most popular automation technologies. That is why we will explain its specificities and requirements for industrial flooring in a dedicated chapter.

Automatized & Robotized Warehouses

AutoStore Systems

AutoStore systems operate by robots moving storage boxes of a given size around a designated rectangular area, which are lowered or lifted on top of the system and then delivered to a designated pick-up point. The advantage of AutoStore systems is that they make very good use of the available warehouse space, are highly suitable for dense storage and can move products quickly and efficiently.

Although the level accuracy requirements for successful installation of AutoStore systems are not particularly stringent, complex specifications must be met by the industrial floor to ensure uncompromised installation.

It is therefore important to consult the right professionals when installing a potential AutoStore system to ensure that your floor is guaranteed to meet the AutoStore system specifications.

Take advantage of our free consultation, during which we will provide you with detailed information and answer any questions you may have about the installation of your AutoStore system!

Automatized & Robotized Warehouses

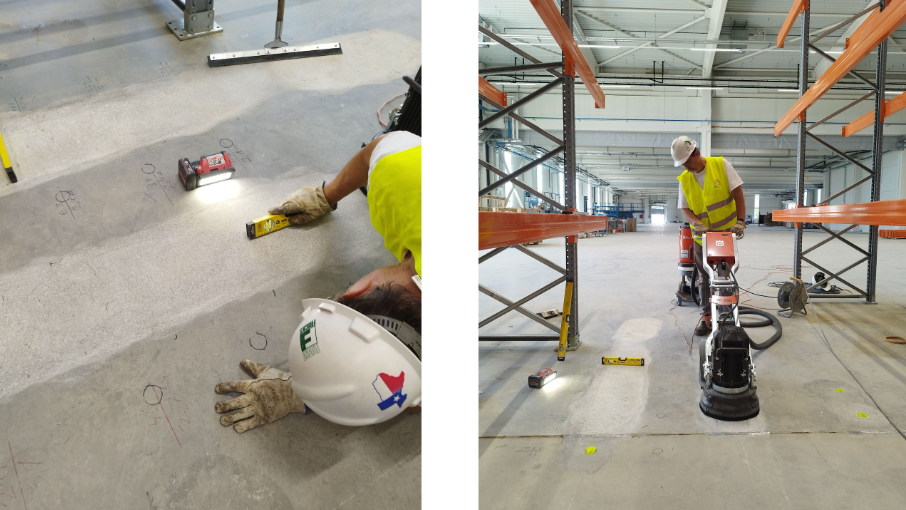

Warehouse automation with corrective grinding

Thanks to our spot grinding technology, we can match any warehouse to any automated or robotized warehouse system. What’s more, for new warehouses and projects, we check everything from the foundation to the finish to ensure that your industrial floor is guaranteed to meet all the requirements of an automated warehouse system!